Remade Textile

Less plastic waste is one of the Schônste wijk’s wishes. I have converted this wish into a workshop experiment to develop plastic waste into valuable materials with basic tools.

In collaboration with Art-fact / neighborhood culture Tilburg, an artist in residence program was set up in the first half of 2020 with me to work on this experiment from different locations.

How are you handling your production waste?

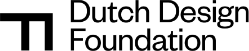

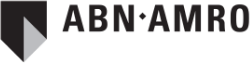

In this project, the starting point was working with (textile) techniques to create the possibility to present visual work while researching the aesthetic value of plastic waste as a raw material. Our goal is to make the process transparent and accessible and to decrease the industrial waste. The materials used, in this project, are plastic bags, fruit nets and plastic bottles. Based on the idea that all the waste in our surrounding can be re-used. The knowledge that has been developed during this process is shared through workshops, events, teaching packages and customized in company advice.

Schônste wijk is a Tilburg neighborhood culture program by Art-fact to make the Goirke-West and Hasselt neighborhoods more beautiful, cleaner and more fun with artistic interventions.

During this livestream I entered into a conversation with Leonne Cuppen (Yksi Connect), Kees van den Boomgaart (Sparkling pastic), Saskia Dellevoet (Art-fact Tilburg), Ron Lambi (Chillabs) about the topic Sharing knowledge about waste as a raw material. Each participant has his own workshop to transform plastic into usable new material, but each in his own way. How can we share and bundle this knowledge with each other?